Quality Control and Why it is Important?

Published: Monday, 18 January 2021

Quality Control and Why it is Important?

Quality control is a process intended to ensure that product quality adheres to a defined set of criteria or meets the requirements of the client. Through the quality control process, the product quality will be maintained, and the manufacturing defects will be examined and refined. This process is highly critical to ensure the quality of EAM™ and Alcogiene™ products in terms of effectiveness and safety.

The quality control process is divided into three separate processes, which are IQC (incoming quality control), IPQC (in-process quality control) and OQC (outgoing or finished-product quality control).

2. Finished-product QC

EAM™ sources from reputable and reliable vendors globally to ensure quality raw materials are used for the production of EAM™ and Alcogiene™ products. For the assurance of consistent quality products, EAM builds accountability into every step of the process through having:

- At least 2 trialed and approved suppliers for each of its raw material

- All incoming raw materials are tested and the verification of the material documented

- Integrated warehouse system where inventories are managed using FIFO

- Constantly evaluating alternate suppliers and vendors through rigorous testing

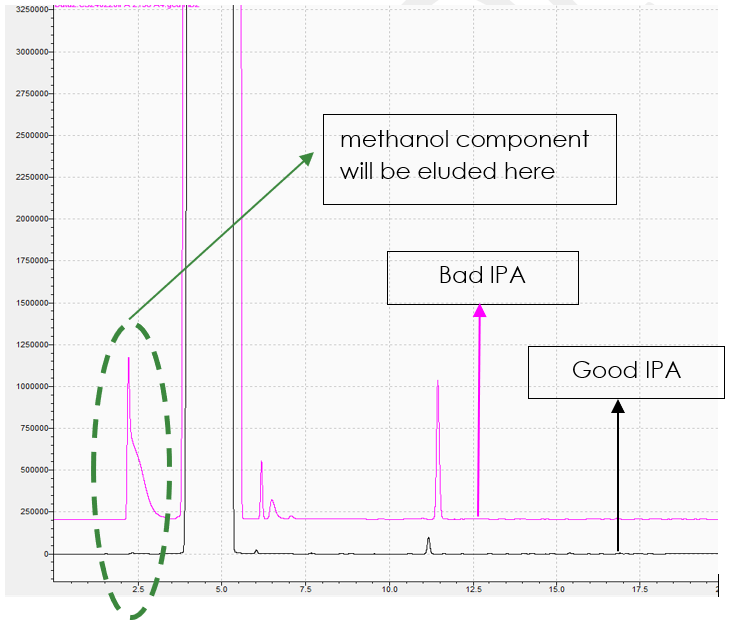

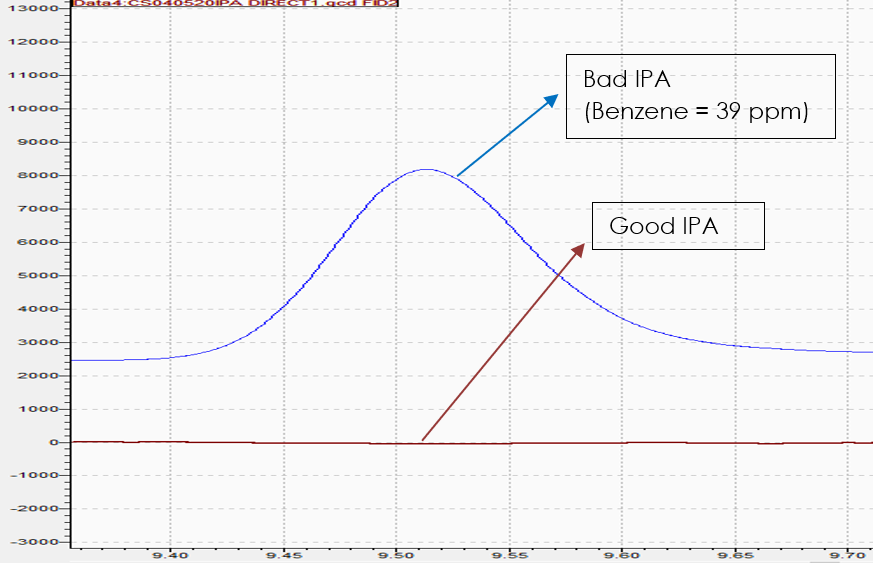

Gas chromatography coupled with a flame ionisation detector to monitor toxic components in alcohol raw materials such as methanol and benzene

Not all alcohol raw materials are the same

Some IPA raw material can have benzene inside.

2. Finished-product QC

All EAM™ and Alcogiene™ products are assigned with an identification number known as lot/batch number. This ensure single EAM™ and Alcogiene™ products are traceable to information such as in coming raw materials quality, production conditions and packaging information. Every process step is verified and documented so that our customer can be sure that EAM takes all effort in assuring product quality.

Using a diamond ATR crystal on an infrared spectrometer to measure the alcohol type and concentration of hand sanitiser

EAM also has a ISO17025 accredited QC laboratory. A reliable and trustworthy testing facility is the backbone of a high-quality hand sanitizers manufacturing business. This laboratory ensures no harmful components such as methanol are present in the products as well as the correct composition of hand sanitizers.

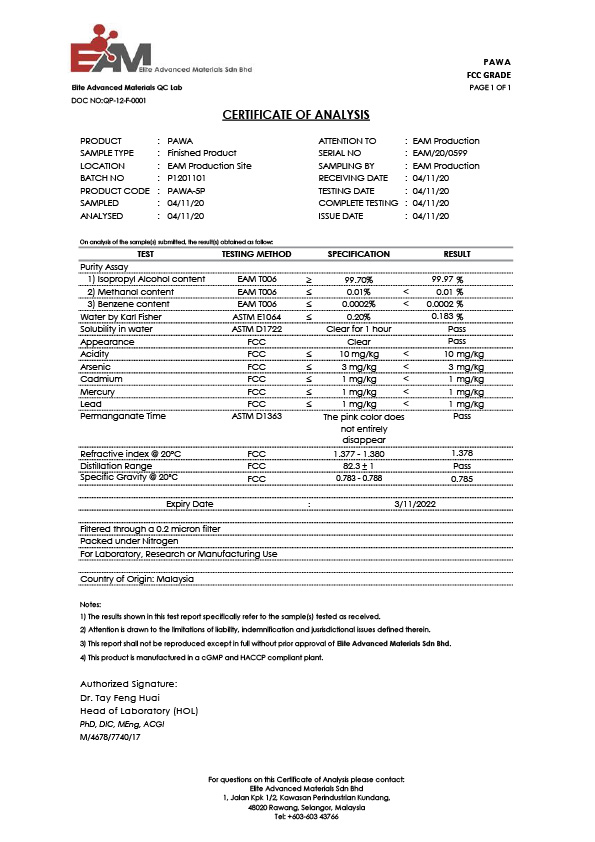

3. Certificate of Analysis

A Certificate of Analysis or COA is a document issued by Quality Control department to confirm that a regulated product meets its product specifications. The document usually consists of the following information:

- Manufacturer Name and Contact Details

- Product Name

- Product Code

- Lot/Batch Number

- Test Parameters

- Test Methods

- Specifications or Requirements

- Test Result (qualitative and/or quantitative)

- Approval Signature and Date

- Traceability Reference (e.g., Serial Number, Sampling Date, Issue Date etc.)

Following is an example of EAM issued COA. COA are available through EAM website at http://eamaterials.com/resources/coa, and are traceable by lot number.